Abstract

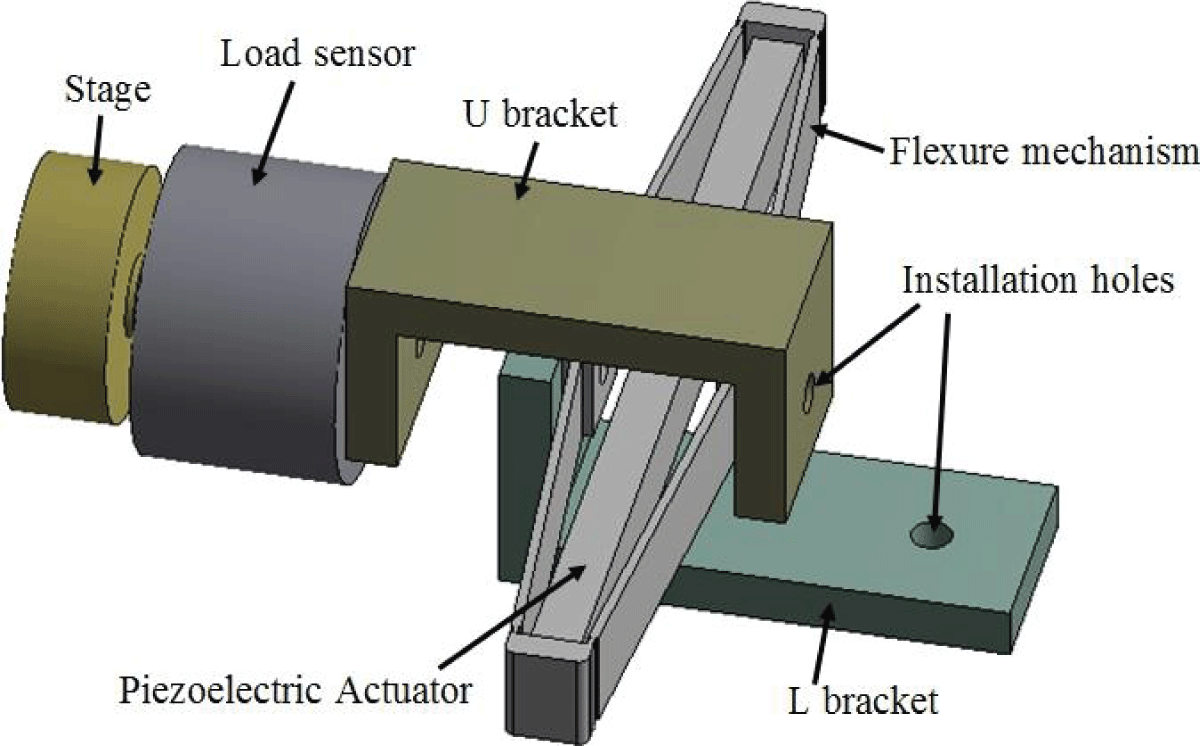

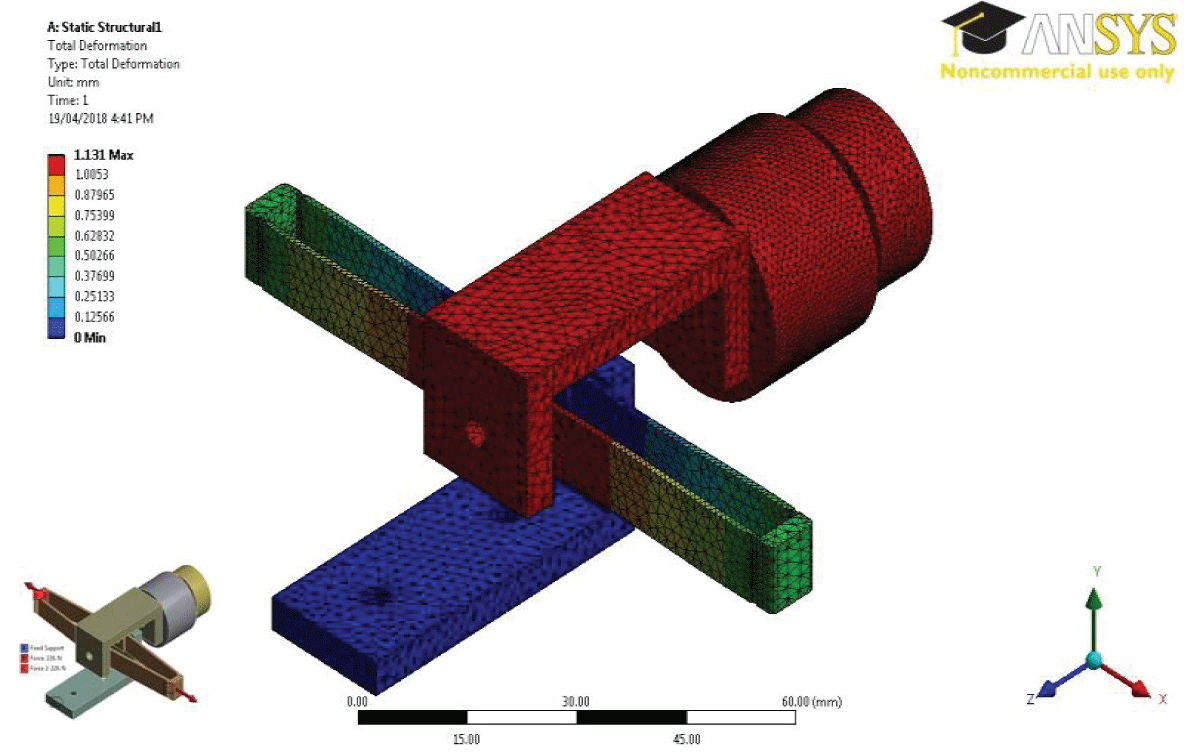

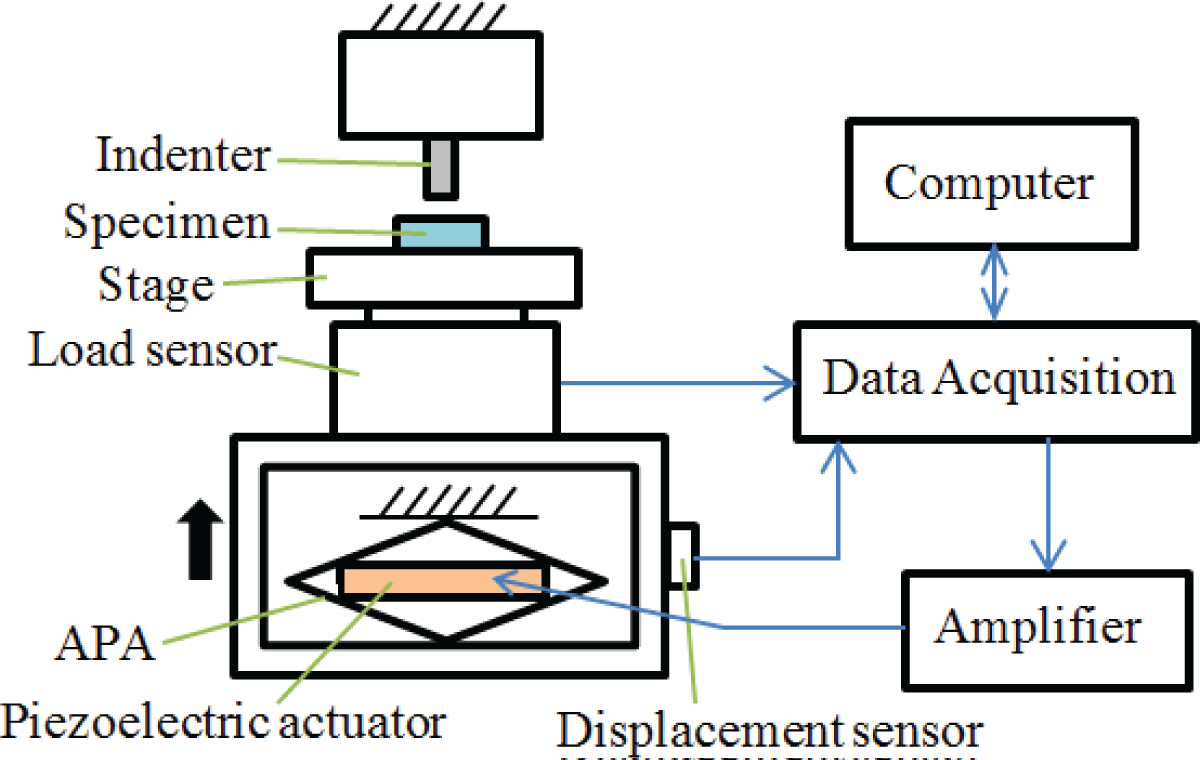

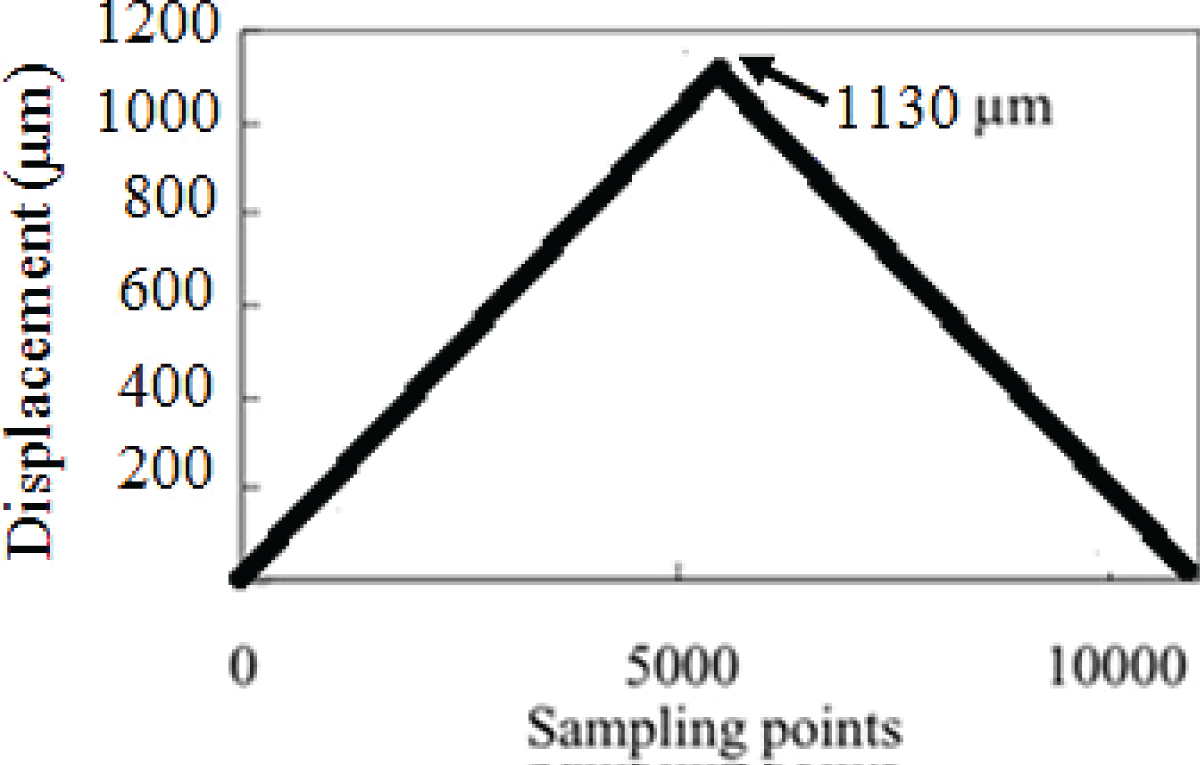

A new design of a fine positioner or high precision driven unit with a large positioning range is proposed for a custom-made in-situ indenter device equipped inside an SEM chamber. The design configuration of the proposed system is size-effective for the confined working area of the SEM chamber. The indentation depths can be precisely varied by controlling the fine positioner driven by a piezoelectric actuator. The main goal is to achieve very deep penetrations toward the bottom layers of tall or large-size scale specimens by single indentation, without the need for sequential indentations. Thus, the proposed design can eliminate the need for sequential adjustments of the specimen position with respect to the indenter tip as currently being practiced by the researchers. The specimen position adjustment after each indentation heavily depends on the coarse positioner and its accuracy level in a sub-millimeter regime which could result in position errors and unwanted lateral forces in the nanoindentation process. Therefore, the sequential indentations technique could lead to considerable variations in the outcomes of nanoindentation tests done on similar specimens. The proposed design will be realized to deploy in the Continuous Stiffness Measurement (CSM) techniques generally used to evaluate elastic properties as a function of continuous penetration depth with high-frequency loading and unloading cycles.

![Prototype of the previously developed in situ nanoindentation device consisted of a precision-driven unit and an indenter unit (reproduction from [20]).](https://www.igminresearch.es/articles/figures/igmin118/igmin118.g001.png)

![Amplified piezoelectric actuator (APF710®) by Thorlabs [10].](https://www.igminresearch.es/articles/figures/igmin118/igmin118.g002.png)