Abstract

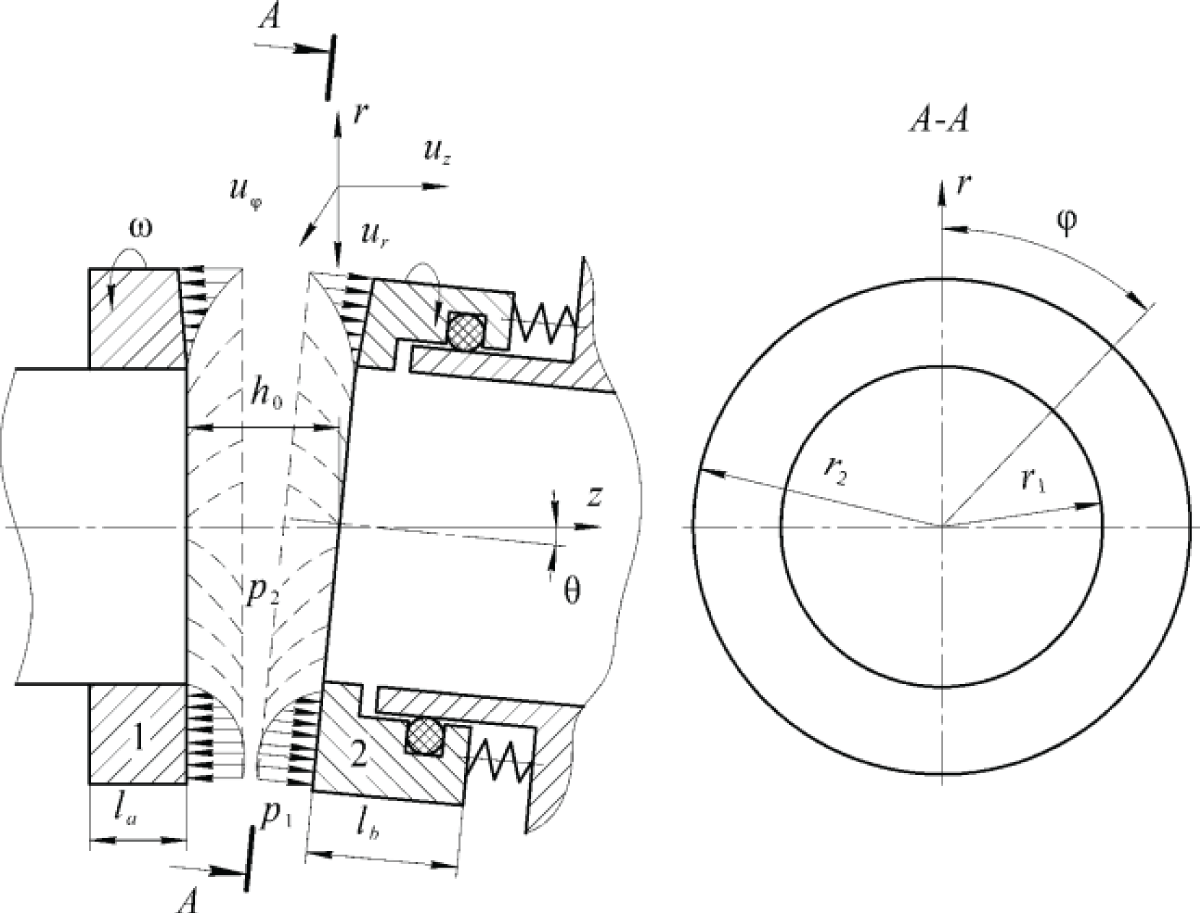

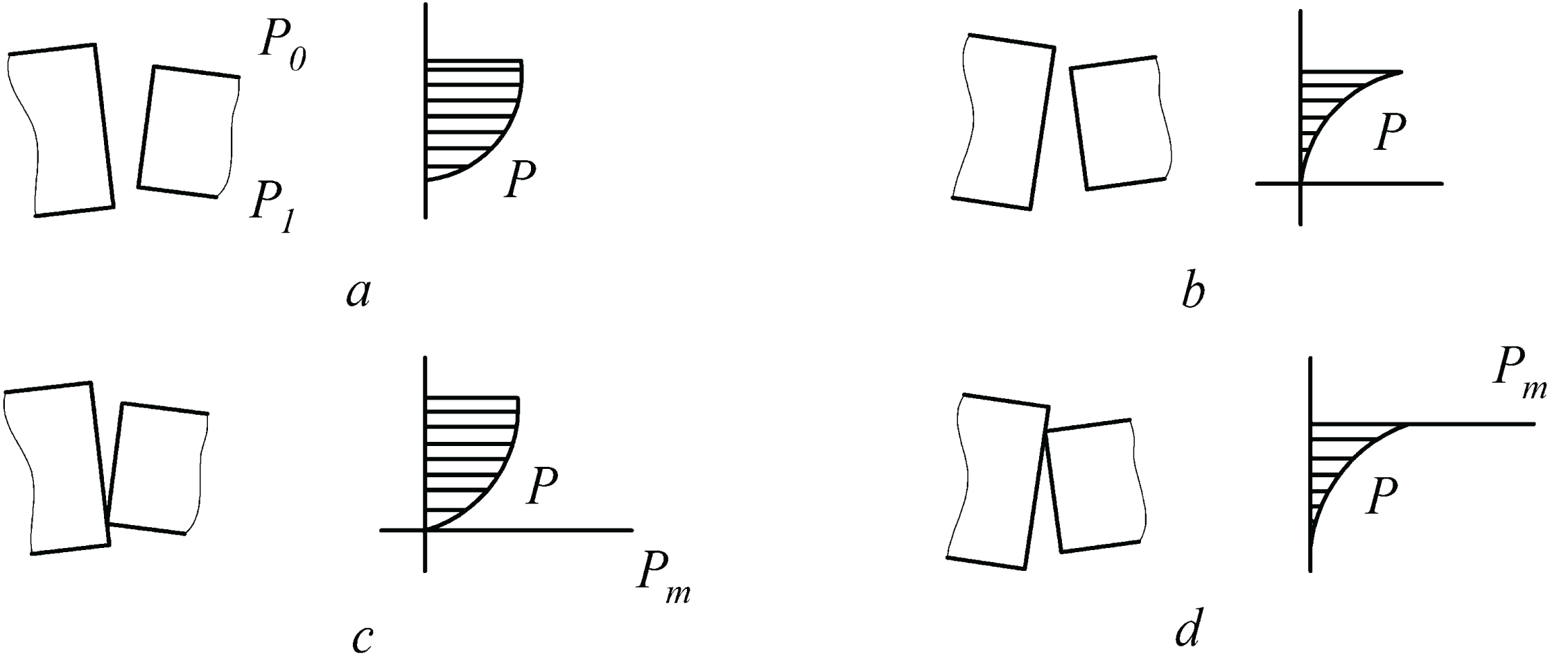

The operating experience of mechanical seals shows that as a result of angular deformations of the rings, the wear of the contact surfaces along the radius is uneven. When designing mechanical seals, it is necessary to calculate the amount of expected leakage through the seal, friction power consumption, as well as the possible durability of the unit. These calculated dependencies and estimates are obtained based on the constructed mechanical seal model. In the area of hydrodynamic load support in the case of a confusor joint or a converging film, the slope of the pressure diagram is such that a decrease in the film thickness increases the hydrodynamic support. This is referred to as enabling stable non-contact sealing operation. The execution of the rubbing surfaces of the interface of the end pair should ensure the formation of the calculated confusor shape of the sealing gap in all modes of operation and axisymmetric pressure fields during the rotation of the rotor.