Abstract

This work represents a part of a larger work, aimed at evaluating the fouling behavior of different flat polymeric membranes for low-pressure applications when placed in contact with industrial wastewater (IWW). To design and understand the operation of a membrane process it is essential to know the fouling mechanisms.

Commercial PVDF and PS membranes were tested under static conditions. The reduction in membrane flux was calculated, before and after the fouling tests. Parameters such as membrane material, pore size, solids concentration, particle size, pH, temperature, flow rate, and pressure were studied to identify the fouling behavior of the membrane.

The strong adhesion of organic molecules on the membrane surface develops a resistance to pore blockage which allows a significant decrease in the flow of clean water.

It is important to note that membranes of the same material, PVDF, but with different pore size (0.2 and 0.5 mm), and membranes of different materials, PVDF and PS, but with the same pore size (0.2 mm) were tested to study the trend of surface fouling to predict it and/or design surface modifications of the membranes employed.

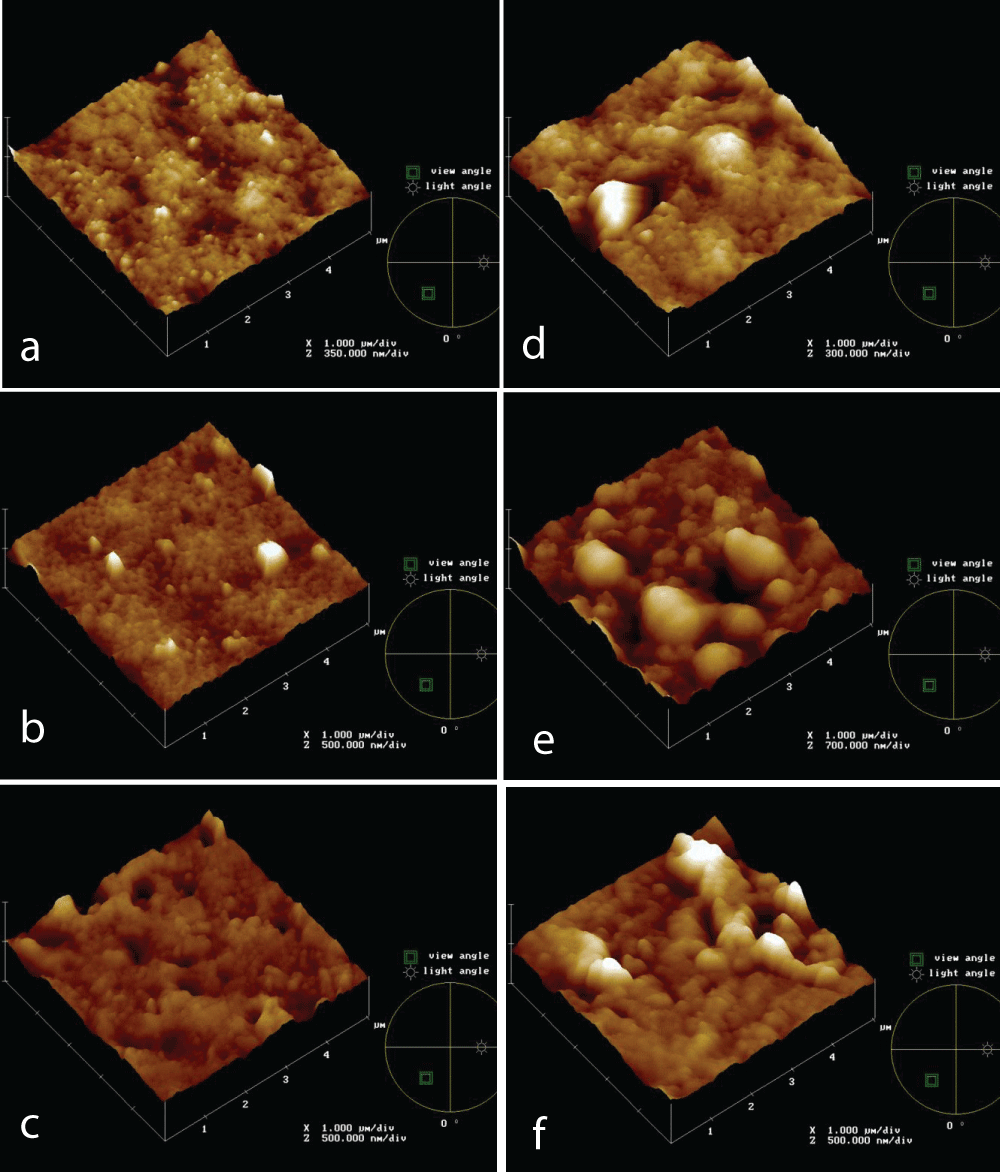

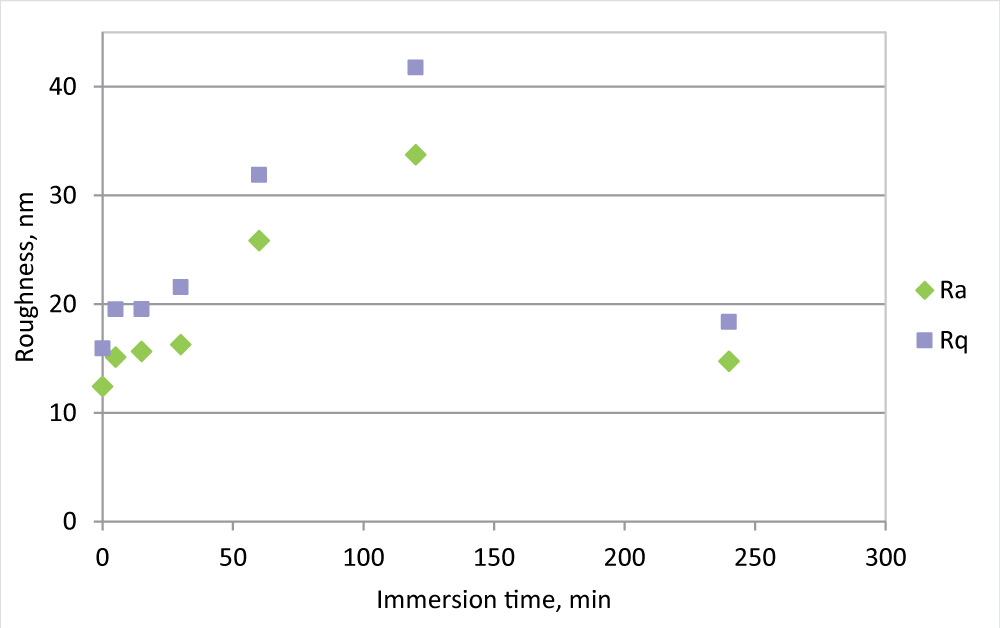

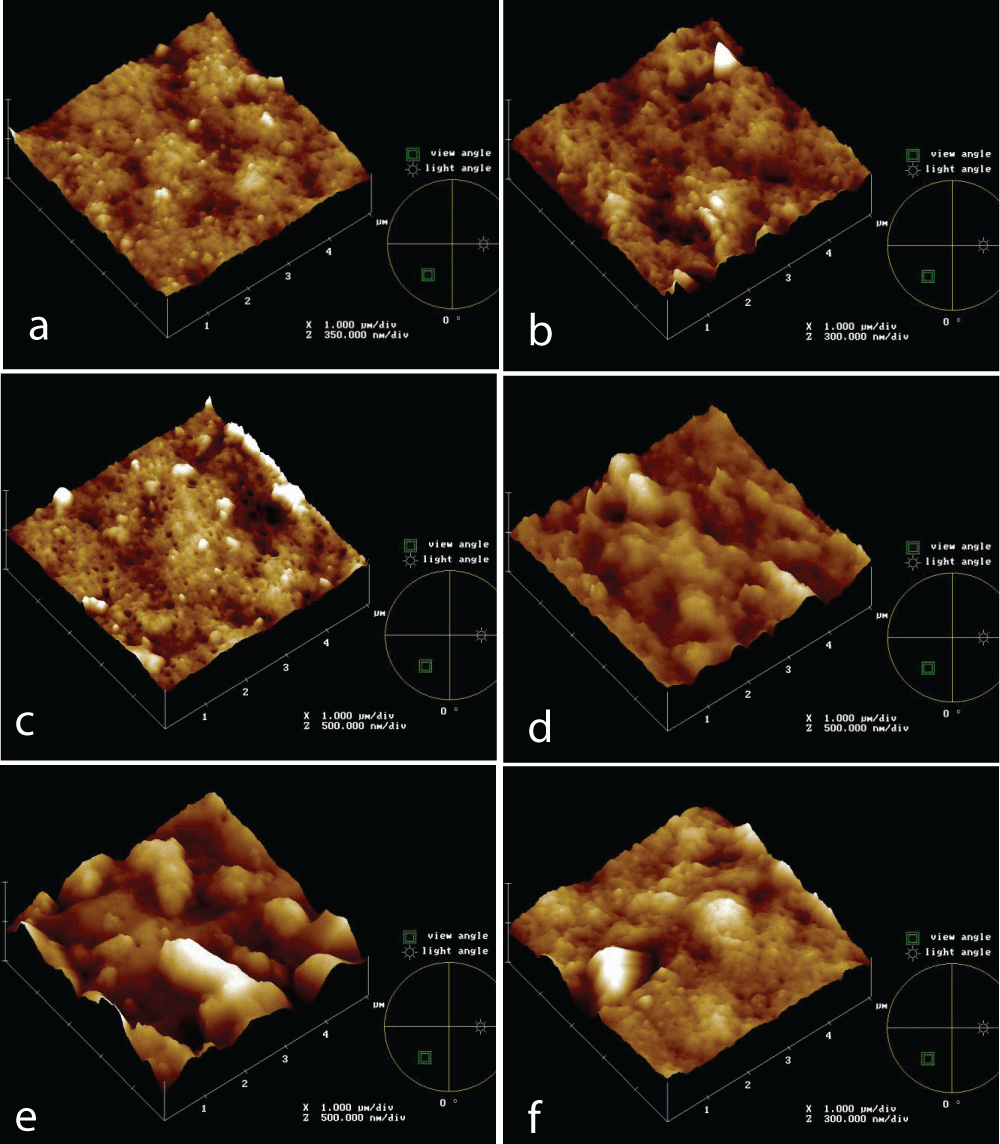

A morphological analysis of the membranes was carried out to understand the fouling mechanism, the fouling times, and the nature of the block that determines the reduction of flow through the membrane itself.

Roughness measurements reveal that roughness goes up to 120 minutes of immersing time in wastewater, but after 4 hours it returns to initial value but with a significant decrease of flux to water.

Understanding the relationship between flux decline, morphology, and roughness role is key to preventing fouling and studying a valid method to clean the membrane.